Laser welding materials are mainly PC, PBT, and PA. Compared to other welding methods, laser welding minimizes possibilities for deformation and stress on internal circuits.

Features

-

Minimal deformation after welding

-

Clean finish

-

Good welding quality

-

Flexibility

-

Minimizing heat affected areas

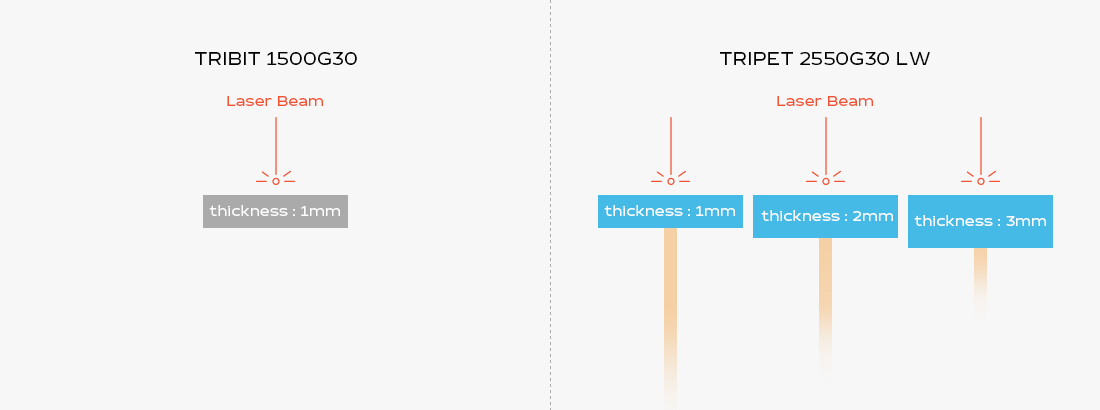

Comparison of Transmittance between General and Laser Welding Grades

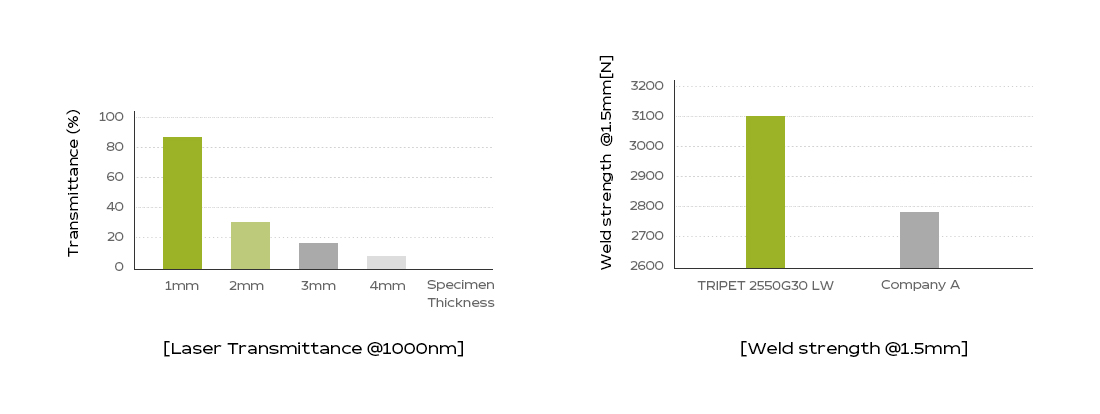

Laser Transmittance and Welding Strength

Applications

Automotive

-

Rear camera module

-

TPMS sensor

-

PCVS

-

EPB sensor

-

Actuator

-

EVCC

Grade

| Grade | Materials | Characteristics | Applications | Datasheet | |||

|---|---|---|---|---|---|---|---|

| TDS | UL | ||||||

| TRAMID 4210G30HU | PA | GF Reinforced,UV Stability | Automotive Interior,Automotive Exterior | 파일 | |||

| TRIBIT NEP1509GN30 | PBT | GF Reinforced,V-0 @ 0.75mm,Non Halogenated,CTI PLC 1 | Automotive Interior | 파일 | 파일 | ||

| TRIBIT 1550G30 | PBT | GF Reinforced,Laser Welding Absorption,High Strength | Automotive Interior,Automotive Exterior | 파일 | |||

| TRIPET 2550G30LW | PET | GF Reinforced,Laser Welding Transmission | Automotive Exterior | 파일 | |||